Clamp Valve

- 产品描述

-

As an important industrial control device, the splint valve is widely used in various fluid control systems. Its core function is to achieve precise control of the flow direction, flow rate and pressure of fluids (such as gas and liquid) by switching or adjusting the opening and closing degree of the splint.

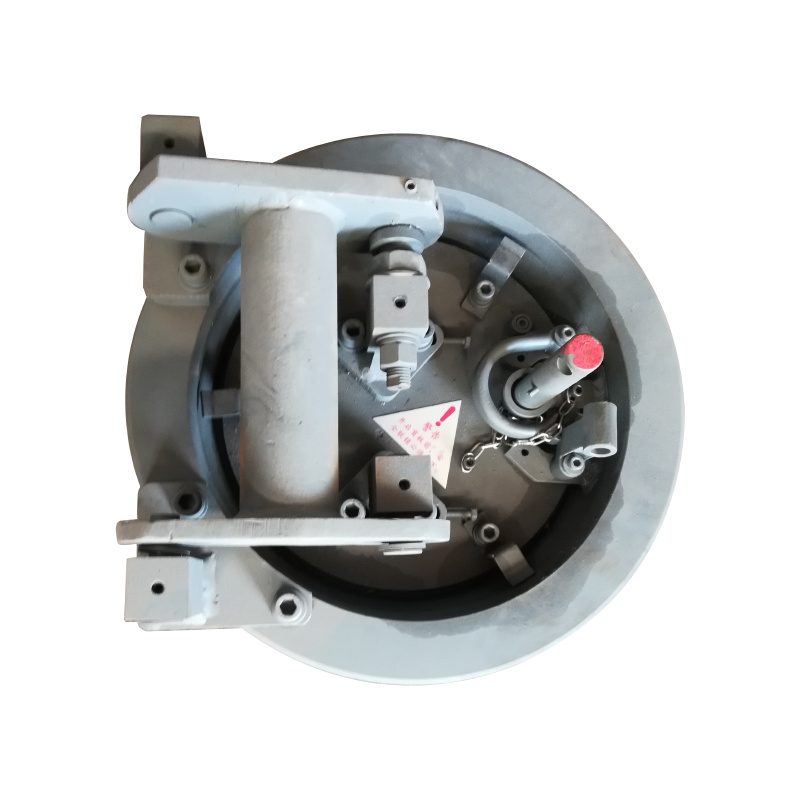

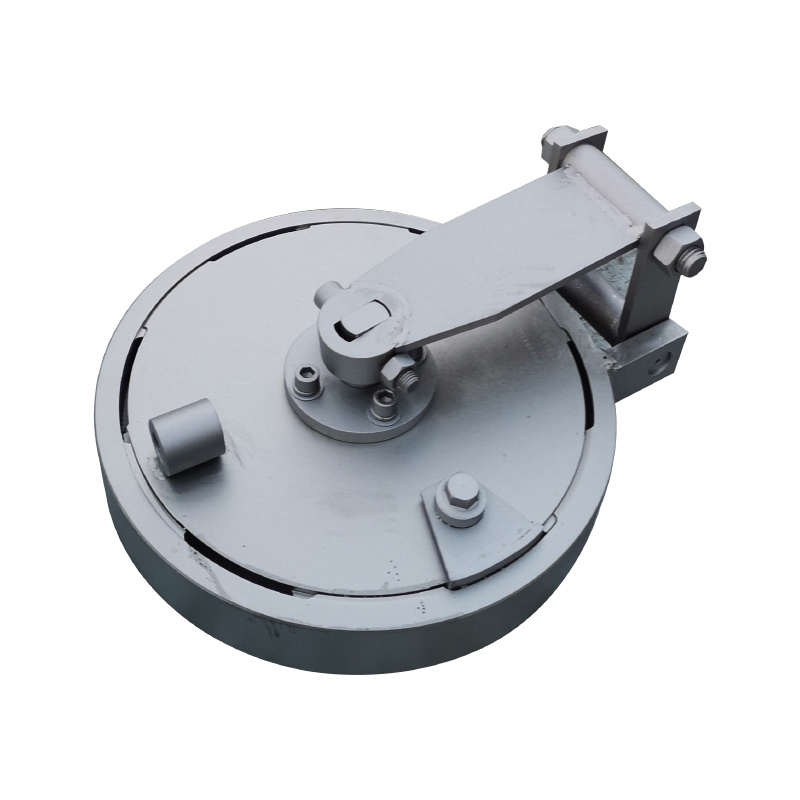

1. Basic structure of splint valve

The splint valve is mainly composed of valve body, splint, drive device and other parts. The valve body is usually made of wear-resistant and corrosion-resistant materials to ensure stable operation in harsh working environments. The splint is the key control component, which can achieve fluid on-off or flow regulation by adjusting its opening and closing degree. The drive device is responsible for providing power to the splint, which can be electric, pneumatic or hydraulic drive to meet different application requirements.

2. Characteristics of splint valve

1. Precise control: By adjusting the opening and closing degree of the splint, precise control of fluid flow direction, flow rate and pressure can be achieved.

2. Wide range of applications: It can be applied to various corrosive, high-temperature and high-pressure fluid control systems.

3. Strong reliability: High-quality materials and advanced manufacturing processes are used to ensure the stability and durability of the equipment.

4. High degree of automation: It can be integrated with various control systems and intelligent devices to achieve automatic control.

3. Application fields of splint valves

Splint valves are widely used in various fields such as petroleum, chemical industry, metallurgy, electricity, environmental protection, etc. In oil drilling, splint valves are used to control the flow direction and flow of mud; in chemical production, they are used to adjust the pressure of corrosive fluids; in environmental protection equipment, they are used to control the emission of exhaust gas.

4. Future development

With the continuous development of industrial automation, the demand for splint valves is also increasing. In the future, splint valves will develop in the direction of intelligence and high performance. Intelligent splint valves will have more functions, such as automatic diagnosis, remote monitoring, etc., to meet the needs of complex industrial environments.

In short, as the core equipment of industrial fluid control, the importance of splint valves cannot be ignored. Understanding the basic structure, characteristics and application fields of splint valves will help us better select and use splint valves, thereby improving production efficiency and equipment safety.

Key words:

Related Products