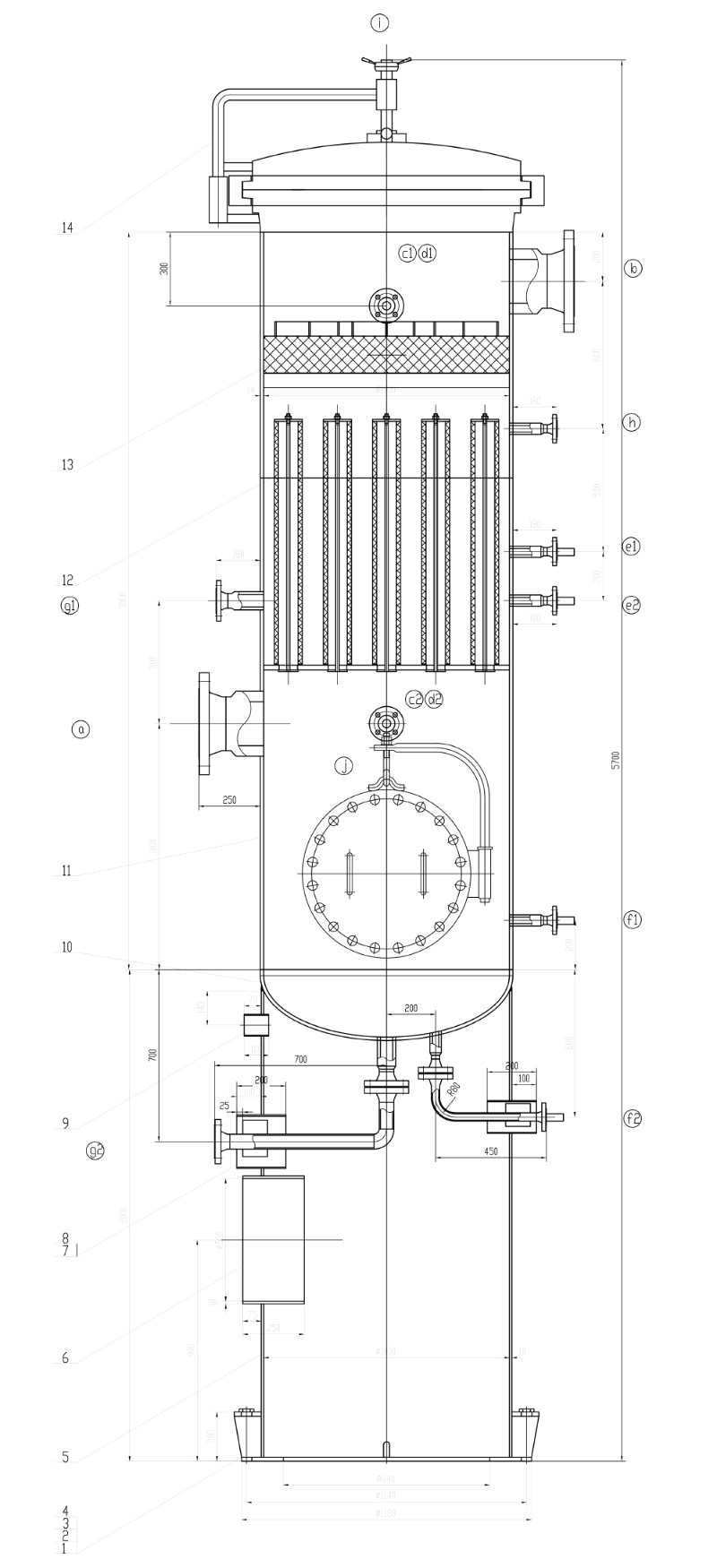

Pipe filter

- 产品描述

-

1. The Q345R steel plate used in the equipment shall comply with the provisions of GB/T713-2014 "Steel Plates for Boilers and Pressure Vessels".

2. The forgings used in the equipment shall comply with the requirements of Grade II and III in NB/T47008-2017 "Carbon and Alloy Steel Forgings for Pressure Equipment" for manufacturing inspection and acceptance, and the steel pipes shall be manufactured, inspected and accepted in accordance with the provisions of GB/T6479-2013 "Seamless Steel Pipes for High Pressure Fertilizer Equipment".

3. Welding is carried out using arc welding. The manual welding electrode grade Q345R is J507, the automatic welding wire grade is H10Mn2, and the flux is HJ431. The welding electrode grade for other carbon steel and low-alloy steel is J427.

4. All opening connections on the equipment should be flush with the inner wall of the container: if the pipe bracket collides, it can be adjusted appropriately.

5. The surface of the connecting pipe and the connecting pipe docking joint with a diameter of DN<250mm on the equipment should undergo 100% MT or PT testing to meet the NB/T47013-2015 standard and be qualified as Level I.

6. After the equipment is manufactured, its anti-corrosion shall be carried out in accordance with the technical agreement and technical specification SPE-0004ME01-01. 7. The orientation of the pipe mouth and anchor bolt seat shall be in accordance with the process pipe mouth orientation diagram.

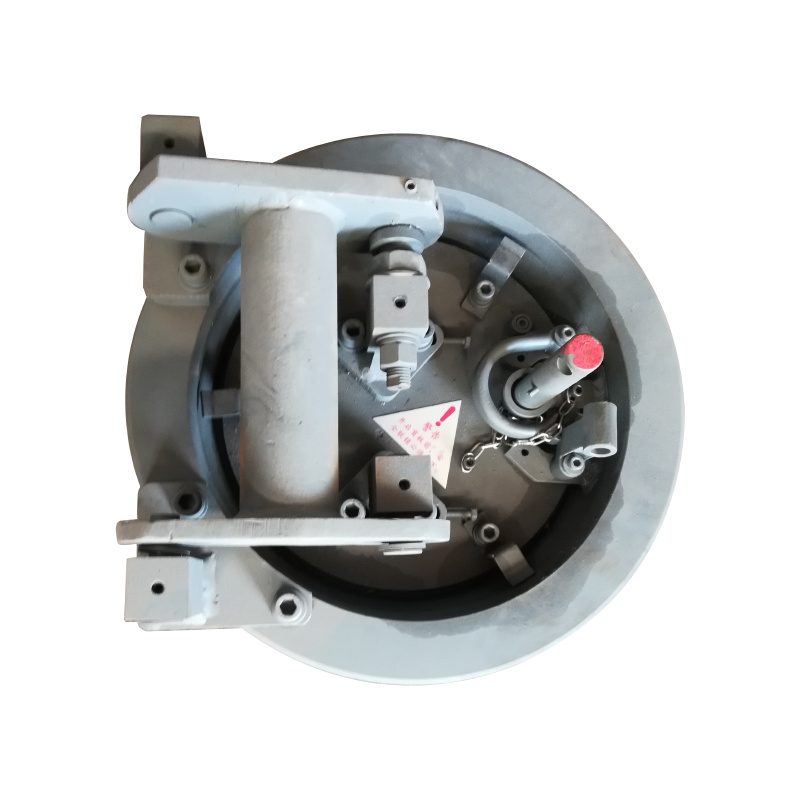

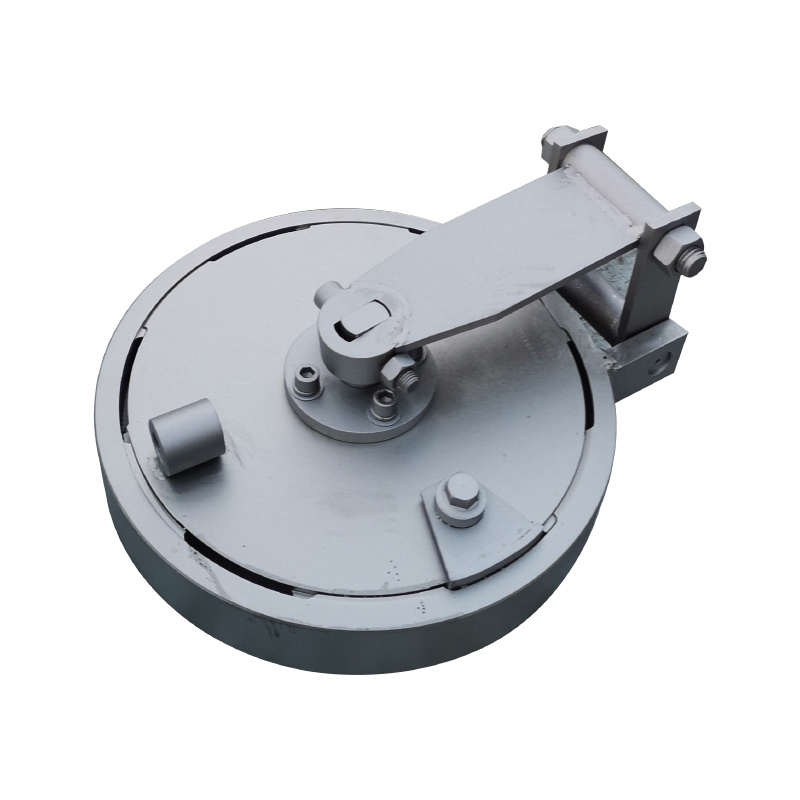

Pipe mouth table Symbol Nominal size Nominal pressure(PN) Connection standards Flange type Connection surface type Purpose or name Extension height(mm) 0 200 63 HG/T20592-2009 WN RF Natural gas imports See figure b 200 63 HG/T20592-2009 WN RF Natural gas exports See figure c1-2 25 63 HG/T20592-2009 WN RF Differential pressure gauge port See figure d1-2 25 63 HG/T20592-2009 WN RF Differential pressure transmitter port See figure e1-2 25 63 HG/T20592-2009 WN RF Local remote transmission integrated liquid level gauge port See figure f1-2 25 63 HG/T20592-2009 WN RF Local remote transmission integrated liquid level gauge port See figure g1-2 50 63 HG/T20592-2009 WN RF Discharge outlet See figure h 25 63 HG/T20592-2009 WN RF Pressure gauge port See figure i 1000 / / / / Speak up quickly / j 450 / / / / Manhole / The outward extension height refers to the distance from the flange sealing surface to the intersection of the outer surface of the equipment and the centerline of the connecting pipe

Key words:

Related Products